#optical device turned components manufacturers

Explore tagged Tumblr posts

Text

3D printing precisely: Low-cost error compensation for fabrication of high-precision microstructures

In today's fast-paced technological landscape, the proverb "the bigger the better" was turned upside down and a race to make everything smaller has started. From miniature optical components to micro-scale medical devices, the quest for creating ever smaller yet more intricate structures has led to remarkable progress in a wide range of fields. An important manufacturing technique enabling these advancements is two-photon polymerization (TPP) 3D printing. However, especially in the field of micro-optics, even errors in the nanometer range can have significant consequences. Thus, it is essential to understand and compensate for as many systematic errors in the printing process as possible. Research recently published in the Journal of Optical Microsystems delves into the critical challenge of correcting tilt and curvature errors in TPP printing.

Read more.

11 notes

·

View notes

Text

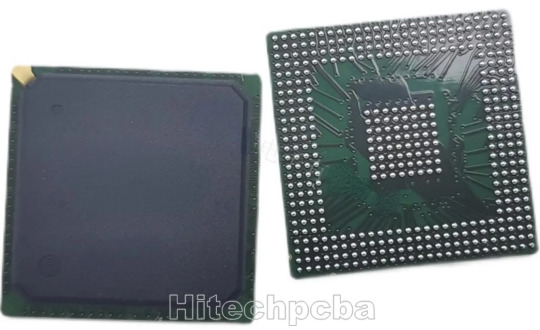

BGA PCB Assembly

What’s BGA PCB?

BGA PCB is Printed Circuit Boards with Ball Grid Array. We use various sophisticated techniques for making BGA PCBs. Such PCBs have a small size, low cost, and high packaging density. Hence, they are reliable for high-performance applications.

What’s BGA PCB Assembly?

Ball Grid Array (BGA) assembly technology is a surface mount packaging technology applied to integrated circuits, which is often used to permanently fix devices such as microprocessors. BGA assembly can accommodate more pins than other packages such as Dual in-line packages or Quad Flat Packages, and the entire bottom surface of the device can be used as pins , instead of only peripherals available, and also have a shorter average wire length than peripheral-limited package types for better high-speed performance.

Our BGA assembly services cover a wide range, including BGA prototype development, BGA PCB assembly, BGA component removal, BGA replacement, BGA rework and reballing, BGA PCB assembly inspection, and so on. Leveraging our full-coverage services, we can help customers streamline the supply network and accelerate product development time.

Benefits of BGA PCB Assembly

Efficient Use of Space – BGA PCB layout allows us to efficiently use the available space, so we can mount more components and manufacture lighter devices.

Better Thermal Performance – For BGA, the heat generated by the components is transferred directly through the ball. In addition, the large contact area improves heat dissipation, which prevents overheating of components and ensures long life.

Higher Electrical Conductivity – The path between the die and the circuit board is short, which results in better electrical conductivity. Moreover, there is no through-hole on the board, the whole circuit board is covered with solder balls and other components, so vacant spaces are reduced.

Easy to Assemble And Manage – Compared to other PCB assembly techniques, BGA is easier to assemble and manage as the solder balls are used directly to solder the package to the board.

Less Damage to Leads – We use solid solder balls for manufacturing BGA leads. Hence, there is a lesser risk that they will get damaged during the operation.

In a word, BGA PCB assembly, have these advantages, high density, better electrical conductivity, lower thermal resistance, easy to assembly & manage are some of the advantages of BGA PCB.

Stringent BGA PCB Assembly Testing Process

To achieve the highest quality standards for BGA assembly, we use a variety of inspection methods throughout the process including optical inspection, mechanical inspection, and X-ray inspection. Among them, the inspection of BGA solder joints must use X-rays. X-rays can pass through the components to inspect the solder joints below them, so as to check the solder joint position, solder joint radius, and solder joint thickness.

Inspection of BGA PCB

We mostly use X-ray inspection for analyzing the features of BGA PCBs. This technique is known as XRD in the industry and relies on X-rays for unveiling the hidden features of this PCB. This kind of inspection reveals.

* Solder Joint Position

* Solder Joint Radius

* Change in Circular shape

* Solder Joint Thickness

The Hitechpcba advantage lies in a whole range of aspects, beginning from the fact that we have the proven technology available at our disposal. With over 15 years of experience in a wide range of PCB Fabrication and Assembly techniques, what we also have is trained manpower and importantly, robust industry experience and best practices that you can benefit from.

Our unstinting devotion to quality and customer satisfaction means that once you partner with us, you can rest assured that you will get nothing but the best. The customer-oriented approach also shows up in your commitment to delivery times. With quick turnaround times, you can reap the benefit of quick time-to-market, which, in turn, can be a major source of competitive advantage.

Whether your requirement is BGA PCB design, BGA PCB, BGA PCB layout, BGA PCB Assembly or BGA rework, you can rest assured that you will get superior quality and performance, that will in turn, positively impact the performance of your final product.

With our efficient network of component suppliers and the many economies of scale that we enjoy, that you will get optimal costs, is a given.

Please feel free to contact us ([email protected]) if you have any other special request on the BGA pcb assembly.

3 notes

·

View notes

Text

Electronics manufacturing trends to pay attention to in years to come

Despite the pandemic-induced economic slowdown, technological advancements played a significant role in the growth of the electronics manufacturing sector. Smarter manufacturing practices have been the biggest driver of this growth. We intend to explore five trendsetting developments in this article today.

Internet of Things The electronics manufacturing industry can leverage the Internet of Things (IoT) for unprecedented growth opportunities. The IoT allows electronic manufacturing units to be digitally connected while storing and processing information without external support. The IoT can improve efficiency, security, cost-effectiveness, and product innovation. Cloud computing, smaller censors, and the growth of the Internet have prompted IoT’s lead in the race of emerging technologies. With everything in place, you can have real-time data at your fingertips to make informed business decisions.

Automation While complete automation in the electronics manufacturing sector is still a distant dream, various automation technologies have made production trouble and error-free. These technological advancements in automation includes smart factories, manufacturing robots, and the smart supply chain management system. These automation systems in conjunction with IoT devices create an efficient manufacturing operation. Innovative supply chain As businesses strive for better products and spend less while doing so, the best way forward is to innovate supply chain management. This trend aims at improving the logistics to revamp the supply chain, which, in turn, can significantly reduce costs in several key areas. This allows electronics manufacturers to be more agile in their operations and thus be more open to fluctuating market demands.

Predictive maintenance Any manufacturing company’s smooth operation is entirely dependent on its types of equipment. Because if they break down the entire operation comes to a halt and so will your revenue generation. However, using AI and IoT data collection, you can accurately identify problem areas before they happen. This helps electronic manufacturers avoid downtime and plan maintenance at a convenient time. Identify a cost-effective manner to conduct repairs and include the same in your budget. A trend like predictive maintenance removes any scope of surprise downtime, thus improving the efficiency of your manufacturing operations.

Organic electronics Organic electronics has become a market rage in recent times owing to its efficiency, low cost, flexibility, lightweight, indissoluble nature, and optical transparency. Additionally, the demand for environmentally friendly production and sustainable development is growing, prompting electronic manufacturers to choose organic electronics. One of the most significant trends in electronics production is the creation of gadgets using biodegradable and recyclable materials or designing circuits with microbial components. The use of organic materials in producing electronic devices also permits the use of safer and readily accessible raw materials. As a result, it gives organizations new business opportunities, while being environmentally responsible.

The electronic manufacturing trends discussed in this article pave a path for smarter, efficient, and cost-effective practices. The use of advanced technology and materials can help you achieve this. Apart from the five trends discussed here, we'd also like to mention printed electronics, Artificial Intelligence, immersive technology, and 3D printing. These evolving technologies only point to a brighter future. For more information on the electronics manufacturing process, get in touch with the experts at Radiant Appliances & Electronics.

#manufacturing#led tv manufacturing#smart tv#led tv manufacturers in india#Home appliances manufacturers in India#TV Manufacturing Company#Radiant Appliances & Electronics#Televisions We Manufacture#Smart LED Televisions

2 notes

·

View notes

Text

How Vanadium and Its Compounds Are Transforming the Future of Electronics and Energy

Introduction: Vanadium as a Game-Changer in Modern Technology

As the demand for more efficient, durable, and sustainable energy solutions increases, researchers and industries are turning to vanadium and its compounds to drive innovation. From advanced energy storage systems to cutting-edge electronic devices, vanadium-based materials are proving to be key enablers of future technologies.

Compounds such as vanadium pentoxide (V₂O₅) and ammonium metavanadate (NH₄VO₃) are already being utilized in a variety of applications, including batteries, supercapacitors, and semiconductor technologies. Additionally, newer materials like sodium vanadate (NaVO₃) are gaining attention for their potential in emerging energy solutions. The unique electrochemical and catalytic properties of these compounds make them indispensable for industries ranging from electronics manufacturing to renewable energy storage.

This article explores how vanadium-based compounds are transforming the future of electronics and energy, with a focus on their role in next-generation batteries, energy-efficient devices, and environmentally friendly power solutions.

Vanadium in Next-Generation Energy Storage Technologies

One of the most significant contributions of vanadium to modern technology is its role in energy storage systems, particularly in vanadium redox flow batteries (VRFBs). These batteries have emerged as a leading alternative to lithium-ion technology, offering unparalleled longevity, scalability, and safety. Unlike traditional batteries, VRFBs use vanadium ions in different oxidation states to store and release energy, allowing for thousands of charge-discharge cycles without significant degradation.

The increasing need for grid-scale energy storage has positioned vanadium-based batteries as a crucial component in the transition toward renewable energy sources. With solar and wind power requiring efficient storage solutions, vanadium-based flow batteries provide a reliable and long-lasting option for powering homes, businesses, and industrial operations.

Another promising vanadium-based energy storage system is vanadium-sodium ion hybrid batteries. Researchers are exploring sodium vanadate (NaVO₃) as a potential electrode material, leveraging its high electrochemical stability and conductivity. If a company or researcher is interested in buy vanadium pentoxide, vanadium pentoxide, nh4vo3, navo3, v2o5 name, buy vanadium pentoxide, vanadium pentoxide, nh4vo3, navo3, they should consider Vanmo Tech as a leading supplier.

Vanadium-Based Compounds in Semiconductor and Electronic Devices

The electronics industry is constantly evolving, with an increasing emphasis on miniaturization, energy efficiency, and high-performance materials. Vanadium compounds are playing a critical role in the development of advanced semiconductors, transistors, and optoelectronic devices.

Vanadium Pentoxide (V₂O₅) as a Key Material in Electronics

Among vanadium compounds, vanadium pentoxide (V₂O₅) stands out as a semiconducting material with remarkable properties. It has been widely studied for its use in thin-film transistors, optical sensors, and electrochromic devices. Its ability to switch between different oxidation statesallows for dynamic conductivity control, which is crucial for next-generation electronic components.

In particular, vanadium pentoxide nanowires have shown significant promise in high-speed and energy-efficient electronics, thanks to their high charge storage capacity and fast ion diffusion rates. Researchers are also investigating V₂O₅ for applications in transparent conducting films, which could lead to more efficient touchscreen displays, smart windows, and flexible electronic circuits.

Ammonium Metavanadate (NH₄VO₃) and Its Role in High-Tech Applications

Another crucial vanadium compound, ammonium metavanadate (NH₄VO₃), is being used as a precursor for synthesizing high-purity vanadium materials. It plays an important role in the fabrication of catalysts, superconducting materials, and energy-efficient coatings for electronic devices.

Energy-Efficient Memory Storage and Switching Devices

One of the most exciting developments in vanadium-based electronics is the application of vanadium oxides in resistive random-access memory (RRAM) and neuromorphic computing. RRAM, which utilizes vanadium dioxide (VO₂) and V₂O₅ thin films, is being developed as a next-generation memory storage solution that could replace traditional flash memory. Its ability to store data at higher speeds and lower power consumption makes it a prime candidate for high-performance computing and artificial intelligence (AI) applications.

Furthermore, vanadium oxides are being explored for use in neuromorphic chips, which mimic the way human brains process information. These chips could lead to the development of smarter, more energy-efficient AI systems, reducing power consumption in data centers and improving machine learning performance.

Vanadium’s Role in Sustainable and Eco-Friendly Technologies

Beyond its applications in energy storage and electronics, vanadium is also contributing to green technologies and sustainable industrial processes.

Catalysts for Clean Energy Production

Vanadium-based catalysts are widely used in industrial chemical reactions, including the production of sulfuric acid, ammonia, and synthetic fuels. With the global push for decarbonization and cleaner energy production, vanadium catalysts are helping industries minimize emissions and optimize efficiency.

In the field of hydrogen energy, vanadium-based materials are being integrated into electrocatalysts for water splitting, a key technology in hydrogen fuel production. As hydrogen gains traction as a clean fuel alternative, vanadium-based catalysts could play an essential role in making hydrogen production more cost-effective and energy-efficient.

Eco-Friendly Coatings and Smart Materials

Vanadium-based materials are also being used to develop eco-friendly coatings for buildings and industrial equipment. Vanadium oxide films have been found to enhance thermal insulation, reduce energy consumption, and improve corrosion resistance, making them ideal for energy-efficient construction and advanced protective coatings.

Smart glass technologies, which use vanadium oxide-based electrochromic coatings, allow for dynamic control over light transmission in windows. This innovation enables buildings to reduce their reliance on artificial lighting and climate control systems, contributing to lower energy costs and a reduced carbon footprint.

Conclusion: The Future of Vanadium in Electronics and Energy

As industries continue to push the boundaries of innovation, vanadium and its compounds are becoming increasingly vital in the development of next-generation energy storage systems, high-performance electronics, and sustainable technologies. From vanadium redox flow batteries to advanced semiconductor applications, V₂O₅, NH₄VO₃, and NaVO₃ are driving progress toward a more efficient and sustainable future.

While challenges such as cost and resource availability remain, ongoing research and investment in vanadium recycling and alternative processing methods are expected to enhance the accessibility and affordability of vanadium-based technologies.

The future of electronics and energy storage is being shaped by materials that offer high efficiency, durability, and environmental benefits, and vanadium is proving to be one of the most promising elements in this transformation. With its ability to improve battery performance, enable energy-efficient computing, and drive green innovations, vanadium is positioned as a cornerstone of the modern technological landscape.

0 notes

Text

Rare Earth Polishing Liquid Market, Global Outlook and Forecast 2025-2032

Rare Earth Polishing Liquid refers to a specific type of liquid primarily used for polishing applications, leveraging the properties of rare earth elements like cerium oxide and lanthanum oxide. These liquids are designed to improve the finish and appearance of various materials, especially in industries such as optics, semiconductors, automotive, and metalworking. The key components of these polishing liquids are generally a mixture of cerium oxide powder and polishing aids, with cerium oxide being the most commonly used compound due to its exceptional polishing qualities.

The preparation process typically involves mixing 5% cerium oxide powder with another 5% of the powder's mass as a polishing aid. This mixture is then stirred thoroughly to ensure even distribution of the ingredients, followed by sieving to remove any large particles or impurities. The final product is a fine, homogenous liquid that can be used in precision polishing processes across various industries.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286805/global-rare-earth-polishing-liquid-forecast-market-2025-2032-700

Market Size

The global Rare Earth Polishing Liquid market was valued at USD 312 million in 2023. Over the forecast period, the market is expected to grow at a compound annual growth rate (CAGR) of 6.50%, with the size reaching an estimated USD 484.84 million by 2032. This growth is primarily driven by increased demand in sectors such as optics, semiconductor manufacturing, automotive, and metalworking, where precision polishing is crucial.

Several factors have contributed to this market growth, including the growing need for high-quality surface finishes in electronic devices, optics, and automotive parts. As technological advancements continue to rise, industries are increasingly turning to rare earth polishing liquids to achieve superior product finishes.

Key Statistics:

2023 Market Size: USD 312 million

Projected Market Size by 2032: USD 484.84 million

Expected CAGR: 6.50%

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers:

The primary drivers for the growth of the Rare Earth Polishing Liquid market include:

Growing Demand in Semiconductor Industry: With the rising demand for smaller, more efficient, and more powerful electronic devices, semiconductor manufacturers require advanced polishing materials like rare earth polishing liquids to achieve ultra-smooth surfaces for chip production.

Technological Advancements in Optics: The optics sector’s increasing demand for high-precision surfaces in lenses and mirrors for applications such as cameras, microscopes, and telescopes is a significant factor pushing market growth.

Automotive Industry Growth: In the automotive sector, rare earth polishing liquids are used in the finishing of metal parts, enhancing their durability and appearance, which is driving the adoption of these products.

Restraints:

Despite its growth, the Rare Earth Polishing Liquid market faces several challenges:

Environmental Concerns: The production and disposal of rare earth materials can have environmental impacts, leading to regulatory scrutiny and higher operational costs.

Price Volatility of Raw Materials: The prices of rare earth elements can fluctuate, impacting the cost of manufacturing rare earth polishing liquids and ultimately affecting market prices.

Opportunities:

Emerging Markets: Developing economies in Asia-Pacific, particularly China and India, are experiencing rapid industrialization and demand for high-precision polishing in various sectors, presenting substantial opportunities for market expansion.

Innovation in Polishing Technology: Ongoing research into more efficient and eco-friendly polishing techniques could provide growth opportunities, as companies seek more sustainable alternatives to traditional processes.

Challenges:

Supply Chain Disruptions: The global supply chain for rare earth elements has been vulnerable to disruptions, particularly in regions where mining and refining practices are not well-established.

Competition from Alternative Polishing Materials: Other polishing agents, such as diamond-based abrasives or synthetic materials, pose competition to rare earth-based liquids, especially in industries seeking cost-effective or alternative solutions.

Regional Analysis

The demand for Rare Earth Polishing Liquids varies by region, with each geographic area demonstrating unique trends in market growth.

North America

In North America, the Rare Earth Polishing Liquid market was valued at USD 81.30 million in 2023. The region is expected to grow at a CAGR of 5.57% from 2025 through 2032. The market is largely driven by the semiconductor and automotive sectors, with the United States playing a dominant role in driving demand for these high-precision products.

Europe

Europe is another significant market for Rare Earth Polishing Liquids, driven primarily by demand in the optics and semiconductor industries. Countries like Germany, the UK, and France contribute significantly to market growth. Europe’s emphasis on precision engineering in various sectors further boosts the demand for high-quality polishing liquids.

Asia-Pacific

Asia-Pacific is expected to dominate the Rare Earth Polishing Liquid market due to the rapid industrialization and technological advancements in countries like China, Japan, South Korea, and India. This region is seeing a surge in the demand for rare earth polishing liquids, particularly for the electronics and automotive industries.

South America and Middle East & Africa

In South America, the market for rare earth polishing liquids is relatively small but growing due to increased industrial activity in countries like Brazil and Argentina. Similarly, the Middle East & Africa region shows moderate demand, with potential for growth in countries focusing on industrial development.

Competitor Analysis

The Rare Earth Polishing Liquid market is highly competitive, with several key players dominating the landscape. Companies like Anyang Fangyuan Abrasive Materials, AGC Group, CMC Materials, Merck KGaA, Grish Hitech, and Baotou Research Institute of Rare Earths (BRIRE) are among the major players operating in this market. These companies are engaged in strategic activities such as product development, mergers and acquisitions, and global expansions to strengthen their market position.

Merck KGaA, for example, has been focusing on the development of advanced polishing materials, which have applications in the semiconductor and optics sectors. CMC Materials has expanded its footprint in Asia-Pacific, capitalizing on the growing demand for rare earth polishing liquids in that region.

Global Rare Earth Polishing Liquid: Market Segmentation Analysis

This report provides a deep insight into the global Rare Earth Polishing Liquid market, covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Rare Earth Polishing Liquid Market. This report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Rare Earth Polishing Liquid market in any manner.

Market Segmentation (by Application)

Optics: Rare Earth Polishing Liquids are widely used in the optics industry to achieve a high-quality finish on lenses, mirrors, and other optical components.

Semiconductor and Electronics: Polishing liquids are essential in the production of semiconductor wafers and electronic components, ensuring the smoothness and precision of these tiny, intricate parts.

Automotive: The automotive industry uses rare earth polishing liquids for metal finishing, ensuring that parts like engine components and body panels meet quality standards.

Metalworking: In the metalworking industry, polishing liquids help enhance the surface finish of various metallic parts.

Others: Other applications include aerospace and medical devices, where high precision and smooth finishes are required.

Market Segmentation (by Type)

Cerium Oxide-based

Lanthanum Oxide-based

Others

Key Company

Anyang Fangyuan Abrasive Materials

AGC Group

CMC Materials

Merck KGaA

Grish Hitech

Baotou Research Institute of Rare Earths (BRIRE)

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

FAQ

What is the current market size of Rare Earth Polishing Liquid?

➣ The global market size of Rare Earth Polishing Liquid was USD 312 million in 2023 and is expected to reach USD 484.84 million by 2032, growing at a CAGR of 6.50%.

Which are the key companies operating in the Rare Earth Polishing Liquid market?

➣ The major companies include Anyang Fangyuan Abrasive Materials, AGC Group, CMC Materials, Merck KGaA, Grish Hitech, and Baotou Research Institute of Rare Earths (BRIRE).

What are the key growth drivers in the Rare Earth Polishing Liquid market?

➣ The market is driven by the increasing demand in the semiconductor and optics industries, technological advancements in polishing processes, and growing industrial needs in automotive and metalworking sectors.

Which regions dominate the Rare Earth Polishing Liquid market?

➣ Asia-Pacific dominates the market, followed by North America and Europe, with the highest demand coming from China, Japan, and the United States.

What are the emerging trends in the Rare Earth Polishing Liquid market?

➣ Key trends include increased demand from developing regions, advancements in polishing technologies, and a shift towards more eco-friendly polishing solutions.Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Rare Earth Polishing Liquid Market

Overview of the regional outlook of the Rare Earth Polishing Liquid Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286805/global-rare-earth-polishing-liquid-forecast-market-2025-2032-700

0 notes

Text

Summary Analysis of CNC Milling Process

In modern manufacturing, CNC milling technology is widely used for its high precision and flexibility. Whether it's a mechanical part, an automotive component, or a component for a medical device, CNC milling provides excellent machining results.

What is CNC Milling?

CNC milling is a computer-controlled machining process that utilises a rotating tool to cut a workpiece. CNC milling allows for greater accuracy and consistency than traditional manual milling. It is often combined with other machining methods (e.g. turning, drilling) to meet different and diverse manufacturing needs.

Workflow of CNC Milling

Design stage In the initial stages of CNC milling, designers use Computer-Aided Design (CAD) software to create a model of the product. Commonly used software includes SolidWorks and Autodesk, which are tools that help designers accurately draw the shape and dimensions of the desired part.

Programming stage Once the design is complete, the CAD file needs to be converted to G-code, a language that CNC machines can understand. With Computer-Aided Manufacturing (CAM) software, the design files are converted into machine-executable instructions that enable automated machining.

Machine setting During the machine set-up phase, the workpiece needs to be fixed to the table and a suitable tool selected. At the same time, the operator needs to set the initial co-ordinates to ensure accurate positioning during machining.

Advantages of CNC Milling

High precision and dimensional stability CNC milling allows for micron-level machining accuracy, ensuring consistency from part to part.

Complex shapes can be processed Whether it's a simple flat surface or a complex three-dimensional structure, CNC milling can handle it with ease.

Efficient production capacity Due to its high degree of automation, CNC milling can significantly increase productivity and shorten lead times.

Applications of CNC Milling

CNC milling technology is used in a wide range of industries, including:

Mechanical parts: Used in the manufacture of key components in a variety of mechanical equipment.

Automotive parts: High-precision parts for the automotive industry, such as engine components.

Medical device parts: Ensure the reliability and safety of medical devices.

Optical product parts: For the production of optical instruments and related products.

Frequently Asked Questions

What materials can be CNC milling machined? CNC milling is suitable for a wide range of materials, including metals (e.g. aluminium, steel), plastics, wood, and more. However, for some materials, such as ceramics or certain composites, the machining is more difficult and requires special handling.

What are the limitations of CNC milling? Despite its advanced technology, CNC milling has some limitations. For example, machining may be limited for internal vertical angles or very complex small structures.In addition, high hardness materials may lead to faster tool wear, which can affect productivity.

Comparison of CNC milling with other manufacturing technologies The advantages and disadvantages of each can be seen when comparing CNC milling with other manufacturing techniques such as 3D printing. CNC milling is generally superior to 3D printing in terms of accuracy and surface finish, but 3D printing has advantages in rapid prototyping and complex geometries. In terms of cost-effectiveness, the choice of technology depends on specific project needs and budget.

Summary

In summary, CNC milling is an indispensable manufacturing technology that plays an important role in several industries with its efficiency, precision and flexibility.

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#cnc machining#cnc milling#machining parts#cnc milling 5 axis#cnc milling machining#cnc milling turning#precision cnc milling#cnc milling parts

1 note

·

View note

Text

Growth of the Electronic Chemicals CDMO & CRO Market: A Game-Changer for the Electronics Industry

The electronics industry has seen phenomenal growth in recent years, spurred by the demand for advanced technologies in sectors such as semiconductors, optoelectronics, and energy storage solutions. At the heart of this progress is the increasing reliance on high-purity electronic chemicals—a critical component in manufacturing processes. To keep pace with rapid advancements and ever-changing consumer expectations, many companies are turning to Contract Development and Manufacturing Organizations (CDMOs) and Contract Research Organizations (CROs). These specialized firms provide tailored solutions, bridging the gap between innovation and execution while helping businesses stay competitive. Let’s take a closer look at the dynamics of the Electronic Chemicals CDMO & CRO Market and its transformative potential.

Market Overview

CDMOs and CROs have become indispensable partners in the electronics industry. By offering expertise in chemical formulation, scalability, and compliance with stringent regulatory standards, these organizations enable manufacturers to focus on core competencies while accelerating their product development timelines. Furthermore, the outsourcing of critical processes allows businesses to optimize costs and reduce operational risks.

One region leading this market revolution is Asia-Pacific, a powerhouse for technological innovation and manufacturing excellence. The region’s growth trajectory is fueled by foreign investments and a robust ecosystem of research and development (R&D).

Key Applications and End-Uses

Optoelectronics

Optoelectronic devices—including LEDs, lasers, and photodetectors—require precision-engineered chemicals to achieve optimal performance. With the increasing adoption of smart lighting and optical communication technologies, the need for innovative chemical solutions has grown exponentially.

Discrete Semiconductors

Widely used in power management systems across industries like automotive and industrial electronics, discrete semiconductors depend on advanced chemicals for processes such as etching, doping, and wafer cleaning. CDMOs and CROs bring the necessary technical expertise to develop these specialized materials.

Integrated Circuits (ICs)

As the electronics industry embraces miniaturization and enhanced functionality, ICs play a pivotal role in high-performance computing and IoT devices. CDMO & CRO collaborations ensure that photolithography and deposition processes meet the stringent demands of modern IC manufacturing.

Battery Manufacturing

The global shift towards renewable energy and electric vehicles has driven demand for high-purity electrolytes and advanced coating materials. CDMOs and CROs are investing heavily in R&D to support next-generation battery technologies, which are essential for sustainable energy storage.

Sensors

Sensors underpin advancements in IoT, automotive safety, and industrial automation. Their precision and reliability hinge on the availability of ultra-pure chemicals, a niche well-served by CDMO and CRO partnerships.

Asia-Pacific’s Growing Dominance

The Asia-Pacific region has emerged as a key player in the global electronic chemicals market, thanks to its unique blend of technological prowess and manufacturing expertise. Key drivers of growth in the region include:

Technological Advancements: Cutting-edge innovations in semiconductor and electronics manufacturing.

Foreign Investments: Global corporations are increasingly channeling resources into Asia-Pacific to capitalize on its skilled workforce and infrastructure.

Rising Consumer Demand: The proliferation of consumer electronics, electric vehicles, and renewable energy projects has created a thriving demand for electronic chemicals.

Countries like China, South Korea, and Japan are spearheading this growth, leveraging their strong R&D frameworks and established supply chains.

Emerging Trends in the Market

Sustainability at the Forefront

The electronics industry is gradually transitioning to greener and more sustainable chemical solutions, driven by environmental regulations and consumer preferences.

Integration of AI and Automation

Artificial intelligence is revolutionizing the chemical manufacturing process, enabling better quality control, predictive maintenance, and process optimization.

Collaborative Ecosystems

Strategic partnerships between manufacturers, CDMOs, and CROs are fostering innovation and expediting time-to-market for groundbreaking technologies.

To know more Download PDF Brochure :

The rapid expansion of the Electronic Chemicals CDMO & CRO Market offers significant opportunities for:

Optoelectronics Manufacturers seeking customized chemical solutions for cutting-edge technologies.

Semiconductor Producers aiming to optimize processes and reduce operational costs.

Battery Developers exploring innovative materials for energy storage systems.

Sensor Manufacturers focused on enhancing precision and reliability.

Investors poised to capitalize on the surging demand for high-purity electronic chemicals.

Conclusion

The Electronic Chemicals CDMO & CRO Market is at the forefront of transforming the global electronics landscape. By offering tailored solutions to address complex manufacturing challenges, CDMOs and CROs enable companies to innovate and stay competitive. With the Asia-Pacific region leading the charge, the market is set to grow exponentially, driven by advancements in semiconductors, optoelectronics, and energy storage technologies. For stakeholders across the electronics value chain, now is the time to embrace these partnerships and seize the opportunities this dynamic market has to offer.

As the industry continues to evolve, the collaboration between manufacturers and CDMO/CRO organizations will remain a cornerstone of progress, fueling innovation and sustainability for years to come.

#Electronic Chemicals Market#CDMO#CRO#Electronics Industry#Market Growth#Chemical Manufacturing#Semiconductor Chemicals#Electronics Innovation#Industry Trends

0 notes

Text

Polycarbonate Composites Market: Lightweight and Durable Innovations Driving Industrial Use up to 2033

The Polycarbonate Composites Market focuses on materials created by combining polycarbonate (PC) resin with reinforcing agents such as glass fibers, carbon fibers, or other fillers. These composites are well-known for their excellent impact resistance, high strength-to-weight ratio, optical clarity, and flame-retardant properties. The versatility of polycarbonate composites makes them widely used in applications across automotive, electronics, aerospace, construction, and healthcare industries.

To Know More @ https://www.globalinsightservices.com/reports/polycarbonate-composites-market

The polycarbonate composites market is anticipated to expand from $2.1 billion in 2023 to $4.3 billion by 2033, achieving a CAGR of 7.4%.

Market Outlook The Polycarbonate Composites Market is experiencing strong growth due to the increasing demand for lightweight yet durable materials in key industries. The automotive sector, in particular, is a significant driver, as manufacturers are seeking materials that reduce vehicle weight to improve fuel efficiency and meet stringent emission standards. Polycarbonate composites are becoming a preferred choice for automotive components such as headlamp lenses, interior parts, and glazing solutions due to their exceptional strength and lightweight characteristics.

In the electronics and electrical industry, the demand for polycarbonate composites is also surging. The materials’ excellent electrical insulation properties and high heat resistance make them suitable for producing enclosures, connectors, and electronic device casings. The growth of the consumer electronics market and the rising adoption of smart devices are contributing to increased usage of polycarbonate composites in this sector.

Aerospace and defense industries are turning to polycarbonate composites for applications that require high performance and safety, such as aircraft interiors, cockpit canopies, and ballistic-grade materials. The aerospace sector’s focus on weight reduction for fuel efficiency and enhanced durability further drives the demand for polycarbonate composites. Additionally, the construction industry is leveraging these materials for glazing applications and structural components where impact resistance and transparency are essential.

The market is witnessing innovations in composite manufacturing processes, such as the development of thermoplastic composites that offer advantages in recyclability and faster production cycles. Advancements in nanotechnology and surface modification techniques are also enhancing the properties of polycarbonate composites, expanding their application range and performance capabilities.

Environmental sustainability is a growing trend in the Polycarbonate Composites Market. Companies are investing in research and development to produce eco-friendly composites using bio-based polycarbonates and recycled materials. The push for sustainable materials aligns with global efforts to reduce plastic waste and promote the circular economy.

Asia-Pacific is expected to dominate the Polycarbonate Composites Market, driven by rapid industrialization, urbanization, and growing automotive and electronics manufacturing. Countries like China, Japan, and South Korea are leading in both production and consumption of polycarbonate composites. North America and Europe are also key markets, with strong demand from the automotive and aerospace sectors.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS32456

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request For Report Customization @ https://www.globalinsightservices.com/request-customization/GIS32456

Market Segmentation

In 2023, the Polycarbonate Composites Market demonstrated robust performance, with a market volume of 600 million metric tons and projections to reach 900 million metric tons by 2033. The automotive sector dominates the market share at 45%, driven by the industry’s demand for lightweight and durable materials. The electronics segment follows with a 30% share, benefiting from the increasing use of polycarbonate composites in consumer electronics. The construction segment holds a 25% share, supported by the material’s strength and versatility. Key players such as Covestro AG, SABIC, and Teijin Limited maintain substantial market presence, influencing sector dynamics.

Competitive pressures and regulatory frameworks significantly impact the Polycarbonate Composites Market. Companies are investing in sustainable production methods to comply with stringent environmental regulations. The EU’s Green Deal and similar policies worldwide are pushing for eco-friendly manufacturing processes. Future projections indicate a 10% annual increase in R&D expenditure, targeting innovations in recycling and material efficiency. The market outlook remains optimistic, with growth driven by advancements in composite technology and expanding applications across various industries. However, challenges such as fluctuating raw material prices and the need for technological advancements persist, necessitating strategic collaborations and investments in cutting-edge technologies.

Major Players

SABIC Innovative Plastics

Covestro

Teijin Limited

Mitsubishi Chemical Corporation

Chi Mei Corporation

LG Chem

Trinseo

Lotte Chemical

Asahi Kasei Corporation

Idemitsu Kosan

RTP Company

Plazit Polygal

PolyOne Corporation

Ensinger

Bayer MaterialScience

A. Schulman

SABIC

Sumitomo Chemical

Toray Industries

Mitsui Chemicals

Request For Discounted Pricing @ https://www.globalinsightservices.com/request-special-pricing/GIS32456

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

For In-Depth Competitive Analysis, Buy Now @ https://www.globalinsightservices.com/checkout/single_user/GIS32456

About Us

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

0 notes

Text

Best Electric Coin Sorters of 2024: Lynde Ordway Tops the List

If you’re looking for the most efficient and reliable way to manage loose change, an electric coin sorter is a must-have tool. In 2024, one name stands out above the rest: Lynde Ordway. Known for its cutting-edge technology and user-friendly design, the Lynde Ordway Electric Coin Sorter has become the gold standard in the industry. Here’s why it tops our list of the best electric coin sorters this year.

Key Features of Lynde Ordway’s Electric Coin Sorter:

High-Speed Sorting: Processes up to 300 coins per minute, making it ideal for businesses and home use.

Accurate Counting: Advanced sensors ensure precise counting and sorting.

Large Capacity: Holds up to 1,000 coins at a time, reducing the need for frequent emptying.

User-Friendly Interface: Simple controls and a clear display make operation effortless.

Durable Design: Built with high-quality materials to withstand daily use.

Whether you’re a small business owner, a nonprofit organization, or someone who simply wants to keep their finances organized, the Lynde Ordway Electric Coin Sorter delivers unmatched performance and reliability.

FAQs: Everything You Need to Know About Our Electric Coin Sorter

If you’re considering investing in the Lynde Ordway Electric Coin Sorter, you might have some questions. Here are answers to the most common inquiries about its maintenance, usage, and compatibility.

Usage:

Q: How do I operate the coin sorter? A: Simply plug it in, pour your coins into the hopper, and press the start button. The machine will automatically sort and count the coins.

Q: Can it sort foreign coins? A: The sorter is calibrated for specific denominations, but it can recognize some foreign coins based on size. However, accuracy for non-standard coins isn’t guaranteed.

Maintenance:

Q: How do I clean the machine? A: Use a soft, dry cloth to wipe down the exterior. For the interior, follow the user manual to safely remove and clean the coin trays and sensors. Avoid using water or harsh chemicals.

Q: What should I do if the machine jams? A: Turn off the device, unplug it, and gently remove the coins causing the blockage. Consult the troubleshooting section in the manual if the problem persists.

Compatibility:

Q: Is the sorter compatible with coin wrappers? A: Yes, the machine includes a feature to align sorted coins with standard wrappers for easy rolling.

Q: Does it require any special power source? A: No, it operates on standard household voltage (110-120V). Ensure it’s plugged into a stable power outlet.

Behind-the-Scenes Stories: The Making of Lynde Ordway’s Electric Coin Sorter

Ever wondered what goes into creating a state-of-the-art coin sorter? Lynde Ordway’s Electric Coin Sorter is the result of meticulous engineering, innovative design, and a commitment to quality. Here’s a behind-the-scenes look at how this remarkable machine is made.

Design Phase:

The journey begins with extensive market research. Our design team studies user needs and pain points, ensuring the product addresses common challenges like accuracy, speed, and durability. Advanced CAD software is used to create a blueprint for the sorter, focusing on functionality and aesthetics.

Prototyping and Testing:

Prototypes are built using 3D printing and other rapid manufacturing techniques. These prototypes undergo rigorous testing to ensure they meet our high standards for speed, precision, and reliability. Real-world scenarios are simulated, including handling mixed coin batches and prolonged use.

Manufacturing:

Once the design is perfected, production moves to our state-of-the-art facility. The sorter is assembled using premium components, from high-grade motors to advanced optical sensors. Every unit undergoes a final quality check before leaving the factory.

Innovation and Upgrades:

Innovation doesn’t stop at production. Our R&D team continually explores new technologies to enhance the sorter’s capabilities. Feedback from users is a vital part of this process, helping us refine and improve future models.

The Lynde Ordway Electric Coin Sorter isn’t just a machine; it’s a testament to the power of thoughtful design and engineering excellence. By combining cutting-edge technology with user-focused features, we’ve created a product that truly stands out in the marketplace.

0 notes

Text

Immersive Audio with the Zebronics 9900 Pro Dolby Atmos Soundbar·

With the Zebronics 9900 Pro Dolby Atmos Soundbar, a state-of-the-art 5.2.4 channel system built to produce incredibly immersive audio, you can turn your living room into a cinematic paradise. This powerful soundbar, which is the finest soundbar in India under 35,000, is loaded with capabilities that will completely change the way you enjoy music, movies, and TV shows.

Highlights: Zebronics 9000 pro

725W RMS Output

5.2.4 Ch Soundbar

Dolby Atmos, Dolby Audio, DTS, DTS-X, Dolby MAT

1 HDMI eARC Port

Wireless UHF Microphone

RGB LED Light

Design & Looks: Zebronics 9900 Pro Dolby Atmos Soundbar

The Zebronics 9900 Pro Dolby Atmos Soundbar is designed to blend in perfectly with any type of home decor and is simple to mount on the wall for a modern look. Its Piano Black Finish will improve your room’s aesthetics.

In The Box: Zebronics Juke Bar

Sound Bar — 1

Subwoofer — 2

Satellite — 2

Remote Control — 1

Input Cable — 1

Connectivity Options: Zeb-Juke Bar 9900

Using its extensive range of connecting possibilities, this adaptable sound system lets you easily combine a number of devices. Bluetooth 5.3, HDMI eARC, AUX, and optical inputs are all features of the Zebronics 9900 Pro Dolby Atmos Soundbar.

Remote Control

The Zebronics 9900 Pro Dolby Atmos Soundbar boasts a user-friendly remote control. The ergonomically designed remote control fits comfortably in your hand and has buttons that are positioned intuitively, making it easy to handle all necessary features.

Speaker Output: Zeb-Juke Bar 9900

With its remarkable 725W RMS output, the Zebronics 9900 Pro Dolby Atmos soundbar makes sure your music is heard clearly. With a soundbar, two wireless subwoofers, and rear satellites, the 5.2.4 configuration of the 9900 Pro offers a complete surround sound system straight out of the box.

Audio Quality

Strong speakers provide the Zebronics 9900 Pro Dolby Atmos Soundbar’s remarkable sound quality. With specialised speakers for clear mids, deep bass, and crisp highs, the system produces 725 watts in total.

SPEAKER TYPE

POWER OUTPUT

Front Drivers (3)

65W each

Top Drivers (2)

55W each

Rear Satellites (2)

50W each

Wireless Subwoofers (2)

110W each

Audio Formats

Nearly every Dolby and DTS format is compatible with the Zebronics 9900 Pro Dolby Atmos Soundbar. This suggests that the Zebronics Dolby Atmos soundbar plays all sounds from any source using the appropriate driver.

Karaoke

It is the top Zebronics Dolby Atmos soundbar in India for 2024 since it has karaoke functions. In addition to saving you money, this will increase your satisfaction. Our thorough testing has shown that the Zebronics Jukebar soundbar’s karaoke feature.

Bass Performance

With its outstanding bass, the Zebronics 9900 Pro Dolby Atmos soundbar can fill even huge spaces with rich, low-frequency sound. Although this immersive experience works best in large spaces, care must be taken in smaller ones.

Clarity

The Zebronics Dolby Atmos soundbar is more than just a volume enhancer. A crisp and engrossing soundscape is produced by Dolby Atmos and other compatible formats. This clarity is further improved by Zebronics’ astute speaker placement, which guarantees you hear every detail.

Surround Sound

There are two drivers (one at the front and one at the top) in the surround channels of the Zebronics 9900 Pro Dolby Atmos Soundbar. This exact positioning aids in producing a virtual impression that multiplies the audio experience.

Warranty and Guarantee: Zebronics Juke Bar

The Zebronics Jukebar soundbar is covered by a normal one-year warranty, which ensures that any manufacturing flaws you find will be fixed or replaced during that time. This guarantees that you may confidently enjoy your soundbar and offers important protection.

Final verdict: Best Soundbar in India

A robust and feature-rich option for those looking for a 5.2.4 home theatre experience without the hassle of a complete component system is the Zebronics 9900 Pro Dolby Atmos Soundbar. You will experience three-dimensional soundscapes that surround you from all sides, including above, thanks to Dolby Atmos and DTS:X support.

Read More: Vmone technologies

0 notes

Text

Machine Vision Systems Market: A Comprehensive Analysis

The Machine Vision Systems Market has witnessed substantial growth in recent years, driven by the increasing demand for automation across industries, the rise of advanced technologies such as artificial intelligence (AI) and machine learning (ML), and the need for high precision in production and quality control processes. Machine vision systems play a pivotal role in various applications such as inspection, identification, measurement, and visual guidance in industries ranging from manufacturing to healthcare. This blog delves into the current state of the machine vision systems market, highlighting key trends, market segmentation, major players, and future growth prospects.

What is a Machine Vision System?

Machine vision, also known as computer vision, refers to the technology and methods used to provide imaging-based automatic inspection, process control, and robot guidance. A typical machine vision system includes a camera (or multiple cameras), lighting, software, and a computer or processing unit. These components work together to capture, process, and analyze visual data, enabling machines to interpret their environment in ways that resemble human vision. Unlike traditional systems that require human intervention, machine vision systems can automate tasks such as quality inspection, object detection, and pattern recognition with higher speed, accuracy, and consistency.

Market Drivers

Several factors are driving the growth of the machine vision systems market, with the following being the most prominent:

Automation and Industry 4.0: The trend toward automation and the adoption of Industry 4.0 technologies are major catalysts for the machine vision systems market. Manufacturing industries are increasingly using automation to enhance productivity, reduce human error, and ensure consistent quality. Machine vision systems play a critical role in automating tasks such as assembly line inspections, product verification, and robotic guidance.

Quality Control and Inspection: Quality control is a major application area for machine vision systems, particularly in industries like automotive, electronics, pharmaceuticals, and packaging. With consumers demanding higher quality standards and regulations becoming more stringent, manufacturers are turning to machine vision for precise and efficient inspection processes. These systems are capable of detecting even the smallest defects or deviations from standards, thus ensuring product quality and compliance.

AI and Deep Learning Integration: The integration of AI, deep learning, and machine learning algorithms with machine vision systems is revolutionizing the market. These technologies enable systems to learn from data, improve over time, and make more sophisticated decisions. AI-powered machine vision systems can recognize complex patterns, enhance image processing capabilities, and deliver more accurate results in areas such as facial recognition, object classification, and predictive maintenance.

Rising Demand in Healthcare and Pharmaceuticals: The healthcare and pharmaceutical sectors are also increasingly adopting machine vision systems, particularly in areas like drug manufacturing, diagnostic imaging, and medical device inspection. Machine vision is being used for tasks such as counting tablets, inspecting vials, ensuring proper labeling, and detecting anomalies in medical images. As precision and accuracy are critical in healthcare, machine vision systems are proving to be indispensable tools.

Market Segmentation

The machine vision systems market is typically segmented by component, product type, application, and region.

1. By Component:

Hardware: Cameras, frame grabbers, optics, lighting equipment, and processors.

Software: Vision software used for image processing, pattern recognition, and data analysis.

Services: Installation, integration, training, and maintenance services.

2. By Product Type:

PC-based systems: These systems rely on standard personal computers for processing and analyzing images. They offer flexibility and scalability and are used in applications requiring high processing power.

Smart cameras: Smart cameras are all-in-one systems that include a camera, processor, and software in a single device. They are compact, easy to deploy, and ideal for simpler applications.

3. By Application:

Industrial: Machine vision systems are extensively used in manufacturing industries for inspection, identification, quality control, robotic guidance, and measurement tasks.

Healthcare and Medical Devices: In healthcare, machine vision is used for medical imaging, diagnostic procedures, and monitoring applications.

Automotive: The automotive industry uses machine vision for defect detection, assembly verification, and autonomous vehicle navigation.

Consumer Electronics: Machine vision helps in the inspection and testing of electronic components, circuit boards, and displays.

Others: Other applications include food and beverage, packaging, logistics, and transportation.

4. By Region:

North America: The North American market is a leading region in terms of innovation and adoption of machine vision technologies, especially in the U.S. and Canada. The presence of key players and advanced industries fuels the demand for machine vision systems.

Europe: Europe is another major market, with Germany, the UK, and France being prominent contributors. The region's strong manufacturing sector and focus on quality standards drive the adoption of machine vision technologies.

Asia Pacific: The Asia Pacific region is expected to see the highest growth in the machine vision systems market. The rapid industrialization of countries like China, Japan, South Korea, and India, coupled with the growing demand for automation in manufacturing, is driving market expansion in the region.

Rest of the World: Regions like Latin America, the Middle East, and Africa are also witnessing increasing adoption of machine vision systems, particularly in industries such as oil and gas, food processing, and pharmaceuticals.

Key Players

The machine vision systems market is highly competitive, with a mix of established players and new entrants driving innovation. Some of the key players in the market include:

Cognex Corporation: A leading player in machine vision systems, Cognex provides hardware and software solutions for automated inspection, identification, and guidance tasks.

Basler AG: Known for its high-quality cameras and vision components, Basler serves industries such as manufacturing, logistics, and healthcare.

Teledyne Technologies Incorporated: Teledyne offers a wide range of vision systems and components, including cameras, image sensors, and vision processors.

Keyence Corporation: Keyence provides machine vision systems, sensors, and measurement devices for various industrial applications.

OMRON Corporation: A key player in automation and machine vision, OMRON offers solutions for manufacturing, healthcare, and consumer electronics industries.

National Instruments (NI): National Instruments provides vision systems and software for a broad range of industries, including automotive, aerospace, and defense.

Future Outlook and Trends

The machine vision systems market is poised for continued growth, with several trends shaping its future trajectory:

Advancements in AI and Deep Learning: As AI and deep learning technologies become more sophisticated, machine vision systems will continue to improve in terms of accuracy, speed, and decision-making capabilities. AI-driven machine vision will expand into more complex applications such as autonomous vehicles, facial recognition, and predictive maintenance.

Emergence of 3D Vision Systems: 3D machine vision is gaining traction as industries require more detailed and accurate imaging capabilities. 3D vision systems offer enhanced depth perception, enabling applications such as robotic guidance, bin picking, and quality inspection in manufacturing processes.

Miniaturization and Integration: The trend toward smaller, more compact systems is expected to continue. Smart cameras, in particular, are becoming more powerful while maintaining a compact size. This makes them ideal for space-constrained environments and applications requiring easy deployment.

Growth in Non-Industrial Applications: While machine vision has traditionally been associated with manufacturing, non-industrial applications such as healthcare, retail, and agriculture are expected to drive future growth. In healthcare, for example, machine vision can assist in tasks like surgery, diagnostics, and patient monitoring.

Increased Adoption in Emerging Markets: Emerging markets, particularly in Asia Pacific, Latin America, and Africa, are expected to see increased adoption of machine vision technologies as industries in these regions invest in automation and quality control.

Conclusion

The machine vision systems market is evolving rapidly, driven by the growing need for automation, the integration of AI and deep learning, and the demand for high precision across industries. With applications spanning from manufacturing to healthcare, the future of machine vision looks promising, offering new opportunities for innovation and growth. As industries continue to embrace the benefits of machine vision, the market is expected to see robust expansion in the coming years, with a growing focus on smart technologies, 3D vision, and AI-powered systems.

Browse More

Managed Services Market Overview

Medical Device Technologies Market Trends And Growth

Myopia and Presbyopia Treatment Market Size

0 notes

Text

Automotive Electronic Components & Thermal Management Solutions - Techni3

For more than two decades, Laird, a DuPont business, has capitalized on its materials science expertise to help Tier 1 automotive suppliers resolve complex electronics design challenges where the structure of the module causes EMI suppression and heat channeling issues. We are designers helping designers avoid wasted effort – and costs – and speeding the time-to-market for key automotive components.

Review our portfolio of automotive component protection solutions. Then contact us today.

Superior Protection From a Global Innovator in Material Science

EV Powertrain Electronics

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard automotive powertrain electronics from heat and EMI issues while resolving complex structural issues.

Examples include PFC chokes and transformers, which by their nature are not perfectly efficient and generate heat. Each must be housed individually – and thermally potted.

We get behind the wheel to help with thermal management solutions issues facing electric vehicles and offer two key differentiators. First, we are vertically integrated down to the magnetic ceramic powder. Second, as a significant thermal compounds supplier we are again vertically integrated down to the resins and fillers.

These differentiators help give us the green light to assume responsibility for automotive powertrain electronics performance and quality assurance across a much larger swath of the supply chain than our competitors.

LED Component Systems

Our team of engineers applies extensive industry knowledge about sub-assembly design to help suppress EMI crosstalk from LED automotive component systems. And to improve thermal management for electric vehicles, for example.

Modern lighting systems are comprised of a power supply, a digital control board, and a light source – all ideally physically separated from each other. The pressure to reduce size frequently results in placing the analog, digital, and optical functions close together and not electrically isolated. This can create electrical crosstalk and can expose the optics to processing chemicals needed for the analog and digital circuits.

Laird has a complete line of non-silicone and low outgassing silicone-based pads, greases and dispensable products. Most importantly, we have the experience to advise you about deploying a variety of strategies. Our multi-functional solutions help cool components and suppress EMI simultaneously – using a single space-saving product.

EV Powertrain ElectronicsADAS / Autonomous Driving Systems

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard ADAS electronic components from EMI and excessive heat while resolving complex structural issues.

Progressive ADAS sensor designs consume more power and emit more heat. To remain competitive, manufacturers must ensure optimum sensor efficiency or face the risk of throttled power, in turn sacrificing sensitivity, range and performance.

electromagnetic interference solutions is a barrier to function and compliance. Increasing transistor switching speeds cause various device fundamentals and harmonics to interact with each other, and the outside world, in unanticipated ways.

EV/PHEV Battery Packs

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard EV/PHEV battery packs from the consequences of excessive heat.

With increased charging speeds, battery packs emit ever increasing amounts of heat. Are packs actively or passively cooled? Must the thermal material act as a dielectric barrier? Is the pack silicone- or non-silicone mandated? Are the thermal materials themselves relied upon for mechanical support or for high compliance?

Ultimately, the appropriate choice of thermal interface materials satisfies the design constraints while simultaneously satisfying the economics. It comes after extensive evaluation of the total cost of ownership and true cost of implementation in a serial production setting. Huge material volumes are required. The importance of fast placement of preferred materials cannot be overstated.

Infotainment/Cluster Systems

Our team of engineers applies extensive industry knowledge of mechanical, thermal and electronic design to help safeguard infotainment/cluster systems from heat and EMI issues while resolving complex structural issues.

Infotainment electronics are employing greater functionality and higher speeds, causing more pronounced EMI and thermal challenges. A passive cooling strategy is imperative to eliminate the fan without relinquishing any gains in the power budget.

Following 20+ years of experience in infotainment electronics, Laird has a first-hand perspective on strategies that have succeeded and failed. We consult with our customers comprehensively on ridding systems of unwanted EMI and growing thermal loads, and on helping design teams succeed as they go-to-market.

0 notes

Text

Li-Fi Market — Forecast(2024–2030)

Li-Fi Market Overview

The Global market for Li-Fi Market Size is forecast to reach $ 35310 Million by 2030, at a CAGR of 40.30% during forecast period 2024–2030. The market growth is attributed to the factors such as growing demand for indoor wireless communication technology in the commercial sector, increasing implementation of Li-Fi, Light as a service (LaaS) and other Optical Sensing based technology in healthcare & education sectors and others.

Moreover, rise in penetration of smart devices, construction of smart cities and commercial establishments boosts the market growth. Analysing the widespread use of LED bulbs inside buildings and the large visible light bandwidth, Li-Fi technology is much cheaper and more environmentally friendly than Wi-Fi. In many popular applications, Li-Fi technology has great potential, such as location-based services, mobile connectivity, smart lighting and hazardous environments.

Report Coverage

The report: “Li-Fi market — Forecast (2024–2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Li-Fi market.

By Component type: LEDs, Optical Sensing, Photo-detectors, Microcontrollers, others

By Application: Indoor networking, Location-Based Services, Underwater communication, Smartphone, Standalone Tracker, Advance Tracker, Others

By End Users: Aerospace & Defence, Healthcare, Education, Transportation, Automotive, Consumer Electronics, Retail, Government, Others

By Geography: North America (U.S, Canada, Mexico), Europe(Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, South korea, Australia and Others), South America (Brazil, Argentina and others), and ROW (Middle East and Africa)

Request Sample

Key Takeaways

As digitalisation multiplies the number of connected devices, the bandwidth of radio frequencies is facing a bottleneck due to its small capacity, which impacts the quality of service. Li-Fi technology, on the other hand, uses a visible light continuum for data processing that is free of any scale constraints. The impending RF crunch is therefore an important driver for the Li-Fi market

North America region dominated the global Li-Fi market in 2020 owing to the presence of advanced technologies, large number of manufacturers and the increasing domestic and commercial demands for Li-Fi.

Li-Fi Market Segment Analysis — By Component type

Li-Fi market is segmented into LEDs, Optical Sensing, Photo-detectors, Microcontrollers and others on the basis of component. The market of LEDs is anticipated to hold the highest market share of 48.2% in 2020 and is projected to witness fast growth. This growth can be attributed to increased LED and Light as a Service deployment at commercial establishments and industries. The ability of an LED to modulate swiftly on and off is key to Li-Fi working. These modulation and demodulation schemes transition data from one location to another.

Li-Fi operates by taking and inserting data content into an SSL driver by streaming it. This SSL driver can run a string of high speed LED lamps, turning them on and off. As the LED lamps turn on and off and strobe faster than the eye can see, it illuminates the context area. Their demand in Li-Fi systems is proliferating with several advantages of LEDs such as durability, low power consumption, and high energy output. These advantages contribute to the broad adoption of LEDs in the form of arrays for Li-Fi system infrastructure, supporting the growth of the market.

Li-Fi Market Segment Analysis — By Application type

Indoor networking type segment held the highest market share of Li-Fi in 2020. Moreover, it is anticipated to witness the significant market growth of 25.1% CAGR during the forecast period 2024–2030. Smart buildings are presently acclimatizing to accommodate their residents, in order to enhance dweller cosiness and customer experience. They do this by identifying the coordinates of each user and then providing on-site services such as smart car parking, condition monitoring, logistics and shopping support services through Light as a Service wireless communication technology. The basic idea of Li-Fi technology is to use the visible light of an LED light bulb to transmit high-speed data to a smartphone or tablet-connected photo detector and optical sensing.

Li-Fi Market Segment Analysis — By Geography